About us

About PushClean™

Technology

The Idea: More than just a towel!

Pushclean more than a towel. An individual answer to a specific need for people on the move.

The biodegradable cellulose-towel along with the application fluid, embedded in the container are ready to use, for everybody, wherever you go.

|

|

The Product

|

|

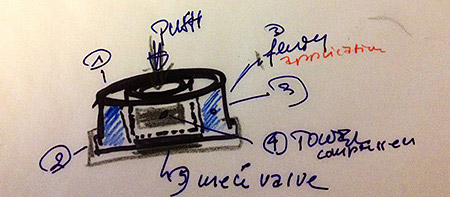

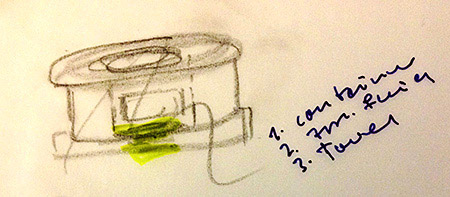

The container (diameter 40mm, height 14mm) is a two-chamber system. In the outer-chamber, the application fluid is held (max.5ml). The inner-chamber holds a compressed cellulose towel (7.5 x 8.5 inches). The two chambers are separated from each other.

Through applied pressure to the middle, the container opens the valve at the bottom and the fluid from the outer-chamber reaches the inner-chamber with the towel. The towel then fully absorbs the fluid and rises vertically. After this contact, the towel can easily be removed, unfolded and put to use.

The Three Components

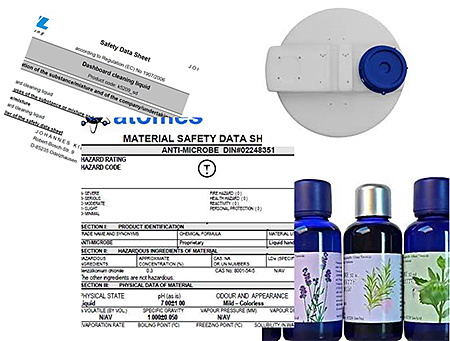

The application fluidA first-class product is the ultimate target of pushclean. For this reason, evaluating and selecting an application fluid of quality is key. All application fluids are thoroughly tested and backed up with a high standard quality and security certification. |

|

|

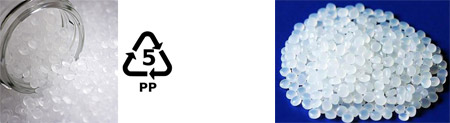

The recyclable container system The main component used is polypropylene (PP). PP group 5 is a semi-crystalline thermoplastic belonging to the group of polyolefins. Polypropylenes are odourless, skin-compatible and physiologically care free. Thus, applicable in the food-sector as well as the pharmaceutical sector. Polypropylenes are recyclable and has the number "5" in the "SPI resin identification coding system.“ There is a great demand for polypropylene to be taken into the collection-system already in place. Yes, we recycle. Together with our partners, we assure that the recycle loop remains closed. |

|

|

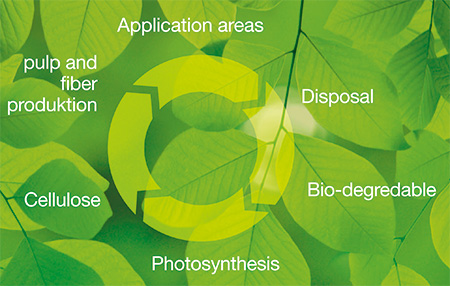

The pressed cellulose towel. Bio-degradable. The chosen raw materials influence the quality of the end product. With the pushclean cellulose towel quality is assured. We unite natural purity, based on the renewable resource wood, with high functionality. This makes the fibers of the towel naturally absorbent and pure. This feature creates numerous products for you, creating a wide application field from hygiene to medicine to technological aspects. The towel is created using 4.6 to 5.7 tons of pressing power and bio-degradable. |

|

The Production

The first test-products left the production belt on April 2010. In 2011, the production-capacity reached 210'000 pieces per month. These products were distributed to selected customers and used for various applications.

Today, three years later we reached a production capacity of 10 million pieces per month.

Upon 2'000m2 two production lines are in place, following this production process:

- sorting of the containers

- positioning the containers

- filling with the application fluid

- employing the compressed towel

- placing the label

| On the production-line 1: Filling of the container with the application fluid. |  |

| On production-line 2: Cosmetic and human application products are being assembled. |  |